One would imagine a watch-strap maker as a lover of horology before starting their business, but for Muhammad Syafiq Badrulizam, it is the other way around. He took an interest in leather-working before he even thought about watches. Even his college background — electrical and electronics engineering — veers wildly from his current vocation.

Yet through his craft, Syafiq has managed to pique the interest of watch enthusiasts from all over the world, gaining one loyal customer after another. The best part is that — having founded his business in 2022 — he has only just begun. Men’s Folio Malaysia speaks to him to learn more about this growing niche industry in Malaysia.

Unexpected Beginnings

Interestingly enough, the pandemic lockdown would be what set Syafiq down this path of entrepreneurship. “I started this journey by making my own cardholder. I had routinely bought card holders up to that point, until I realised I could probably make one myself. I was interested in just leather at first. But in the blink of an eye, I would end up with my strap-making business.”

Getting nudged into this niche was a serendipitous affair. Syafiq’s father would gift him a Seiko 5, and this particular model came with unconventional lugs. Aftermarket straps for this design were rare, and that prompted Syafiq to create one specifically for that watch.

Upon completion, he shared this strap on social media, which drew the attention of his friends. Soon, he would receive requests to make more straps, and that would be the birth of MSBespoke Straps.

The Turning Point

While he did enjoy a warm reception from the get-go, Syafiq would gain the most traction after putting his straps up for sale on Carousell. It is here that a watch enthusiast would discover his products, resulting in a chain of recommendations that would provide Syafiq with a steady stream of orders. In the corner of his studio is a stack of invoices for his customers of the month, who hail from all parts of the world. Clients from the United States, Switzerland, Australia, New Zealand, and many more, are part of that stack.

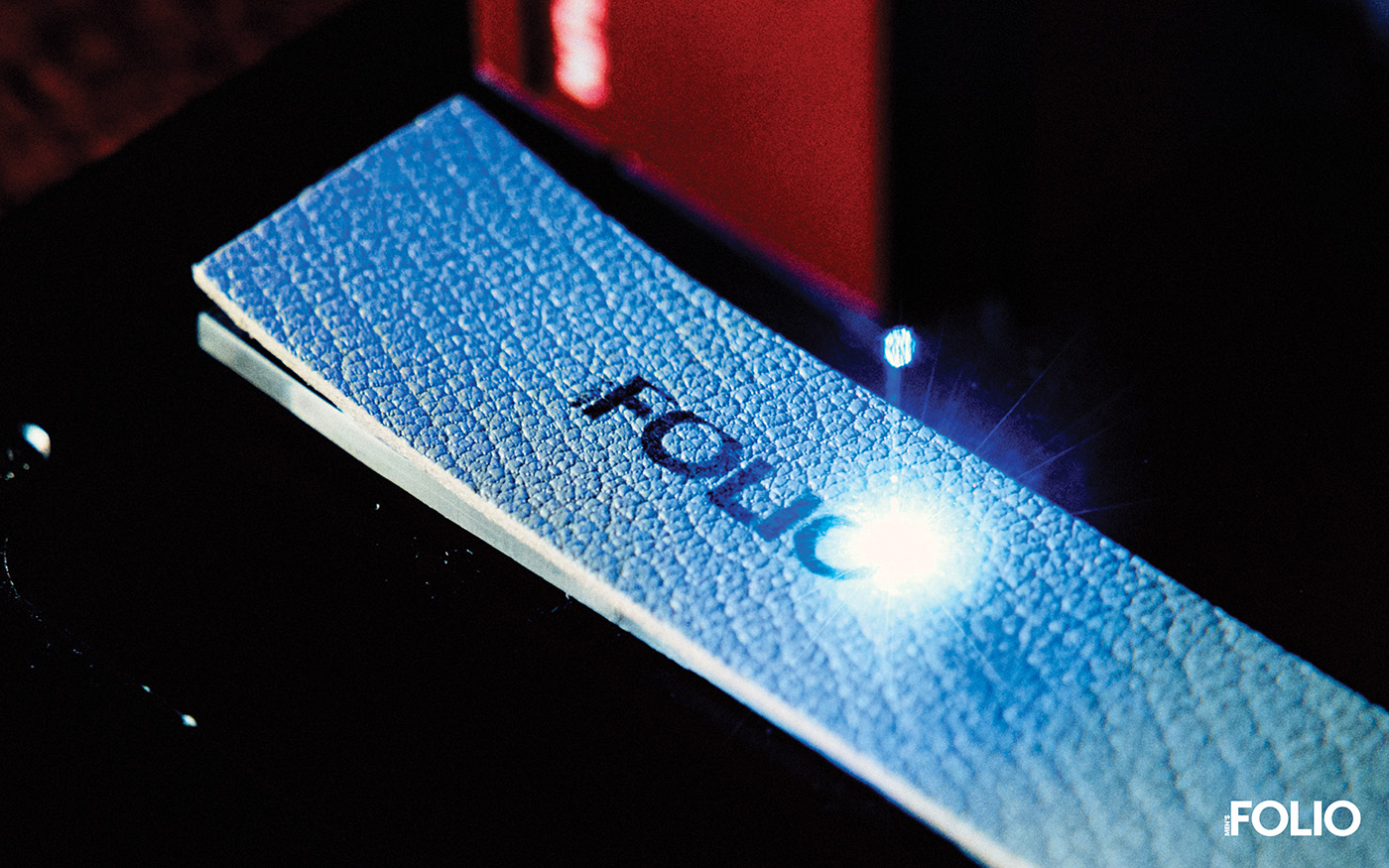

Another major milestone in his journey would come in the form of a favourable review by the famous watch blog Fratello Watches. “If he keeps creating straps as he does now, he will have nothing to fear,” states the article. And after watching how Syafiq created a custom strap-keychain for Men’s Folio with such proficiency and speed, we find ourselves agreeing with that statement.

Sharpening His Axe

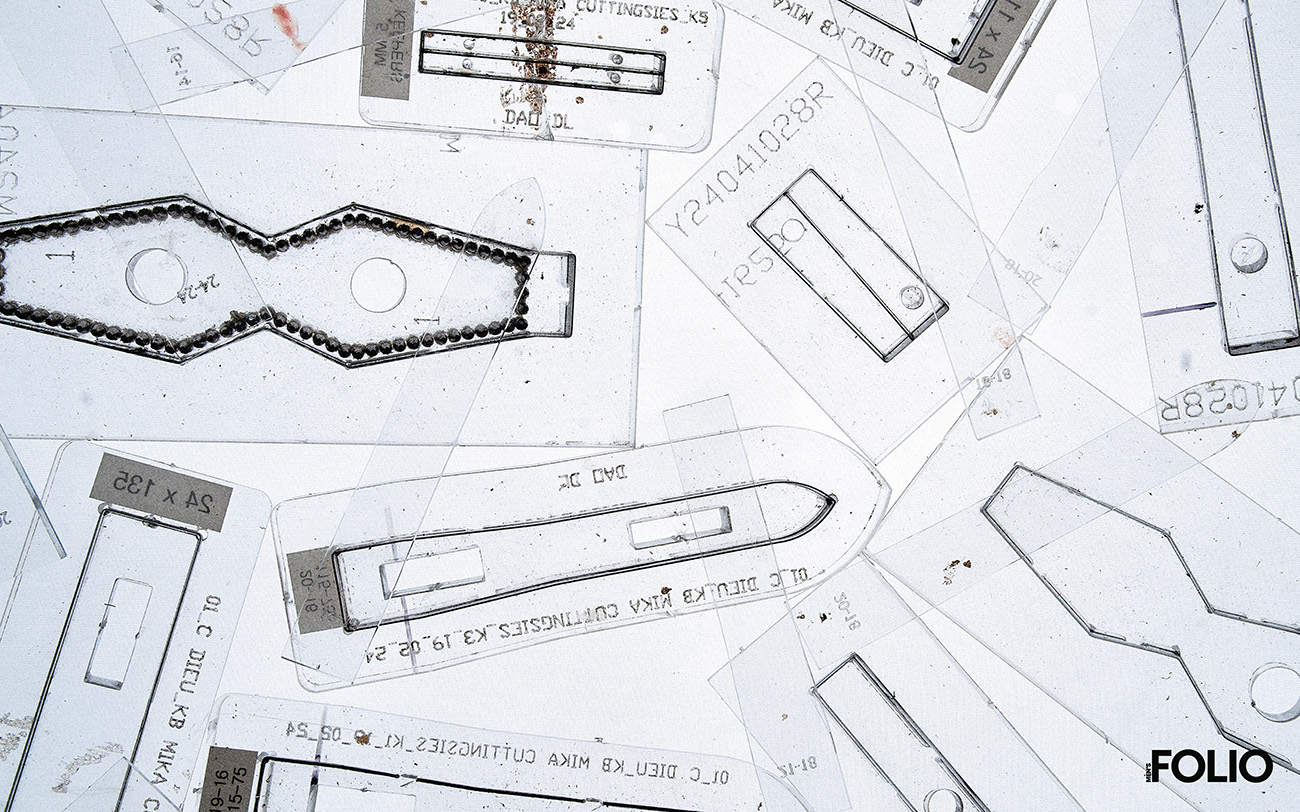

Syafiq is self-taught, and like many other craftsmen who learn on their own, he started out crafting straps with cheap tools and materials. He learnt pretty quickly that tool quality can make or break the results.

Take the pricking tools, for example. When you look at the stitching on watch straps and you might now be aware of just how much effort goes into ensuring an accurate stitch. With this tool — one of the pricier ones in leather working — he is able to mark and puncture proper holes to ease the stitching process. Contrast this by poking each hole manually while not causing unnecessary trauma to the leather and you can see how gruelling it can be to just stitch across four inches of leather. Yet, Syafiq sees this as a rite of passage in his craft.

“Even though I found out late that proper tools allow me to do a better job, I would not have it any other way. Sometimes it takes doing something the hard way to discover which tools you actually need. Besides, should I have lost interest, I wouldn’t have wasted a lot of money,” says Syafiq.

It is inspiring to see how far he has come, from a man with two tools to a roomy studio in Banting, Selangor, with a much larger selection of tools at his disposal — from laser machines to skiving knives. He has invested both in quality equipment and in materials.

Photography Joe Ee

Styling Liew Hui Ying

Once you are done with this story, click here to catch up with our latest issue.